Mar 24, 2016 Oil cooled welding machine. AJ the Automobile Engineer. Duration: 4:06. AJ the Automobile Engineer 10,957 views. WORLD'S BEST TREE FELLING TUTORIAL! Way more information than you ever. Rainbows: 16:57:20: 641 forum posts 182 photos: I got a big set of welding equipment, sticks, masks, welder, etc. The main highlight, the welder is a Pickhill Bantam and originally thought 'Oh darn, its a 3 phase one I will have to sell it'. Jul 05, 2018 Oil filled welder i have a pickhill bantam 180 that broke on me a few weeks ago, i had it checked out and the coil that has the tappins off it for the weldind side. I'm not familiar with Olympic, I think it's just another variation of Oxford and Bantam oil cooled welders. Jd 246 Manual. Try to find a manual online.

Old oil cooled welder 30amp to 180 amp Not sure if it works just blows fuses so possibly good for spares or repairs but got to be worth the asking price in scrap. Collection near lumphanan £30 The pickhill bantam oilcooled welder spares or repairs in Banchory, Aberdeenshire Gumtree. Problem with old-syle oil-imersed arc welder Showing 1-40 of 40 messages. Problem with old-syle oil-imersed arc welder: orion.@virgin.net: 7/16/13 10:19 AM: Hi all, I think the arc welder I have may be faulty. It's an old Olympic one from the early 80s and looks indistinguishable from an Oxford of the same vintage and amperage.

You're right, there's no gauges on it, I did find a couple of pictures on the web of what the top looks like (going out there this weekend to try and spark it up, see what's what) and will see if these relate. My father reckons:

'the amps are 20 to 180 and 30 to 135, the volts are 50 or 80 one setting is coarse'

Sounds about right, and he has the full 3-phase supply out there so roll on this weekend. But first, I need to get myself some rods and a mask. I'm hoping to weld a small bracket on a tailgate that fell off so it's going to be low-power for first attempt.

Can anyone advise what rods I might need for the steel bracket on the tailgate for a land rover ? Sorry, I know this is probably a pretty newbie-ish question but it would be good to get it right if I could rather than spend my time worrying if I'm doing it right :)

Recommends for a decent-ish (under £100 please!) auto-darkening helmet would also be handy, thanks :)

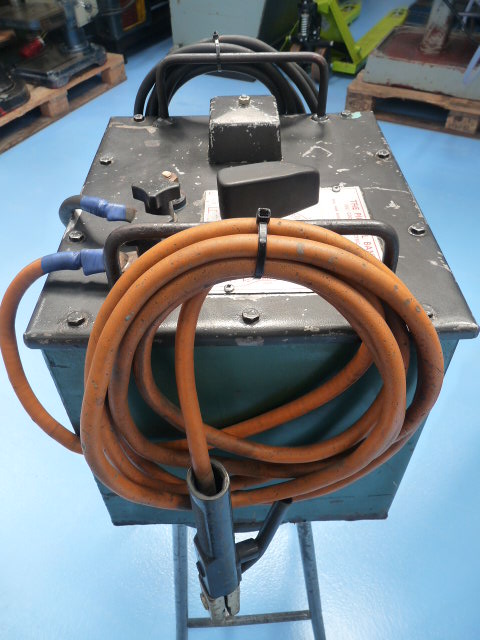

I'm pondering the question of whether I need a bigger welder. I

currently have a Cytringan 'Bantam' 180 A oil-cooled machine. It's

almost identical to the more common Pickhill and Oxford 'Bantam' sets.

Perhaps users of these British oil-cooled machines could give me their

thoughts here?

I have build a lot of stuff using 3 mm thick mild steel. My current

welder copes with this comfortably. A while ago I switched to using 6011

electrodes instead of 6013 because I wasn't happy with the strength of

the welds I was getting and was also having some problems with slag

inclusions in awkward welds. 6011 electrodes are giving me much stronger

welds, but need a higher open circuit voltage to strike an arc. So now I

am using the 80 V terminal on my welder instead of the 50 V terminal.

This is still fine for welding 3 mm and 4 mm steel with 3.25 mm

electrodes as it gives an output up to 120 A. But I have bigger projects

in mind. I want to make a chassis for my phase convertor and a frame for

a hydraulic press. These will require at least 6 mm steel. I want the

welds to have a similar strength and stiffness to the parent metal. In

other words I don't want to be using thicker steel for little gain. So I

want to keep using the 6011 electrodes which I've been very pleased

with. But I'm not sure that I'm going to get adequate penetration in a

single pass using 3.25 mm electrodes on my current machine. I'm not sure

if I should move up to 4.0 mm or 4.7 mm electrodes. And I don't want to

be struggling with a task of which my welder is barely capable.

Pickhill Bantam Oil Welder Manual Download

So does anyone have strong feelings about whether or not my welder is up

to the job? If I was to get another machine I would almost certainly go

for another Oxford-style oil-cooled machine. Probably a 300 A @ 50 V /

200 A @ 80 V machine. A fine current adjustment would be nice too. I

believe there's a machine in the Oxford range which roughly meets this

specification. I also like the really old cube-shaped English Electric

machines, but I'm not sure that they have an 80 V output. Anyone in the

Midlands got an idle machine they want to sell?

Best wishes,

Pickhill Bantam Oil Welder Manual Parts

Chris